XTO - Thermal Transfer Overprinter

Thermal Transfer Overprinting how it should be

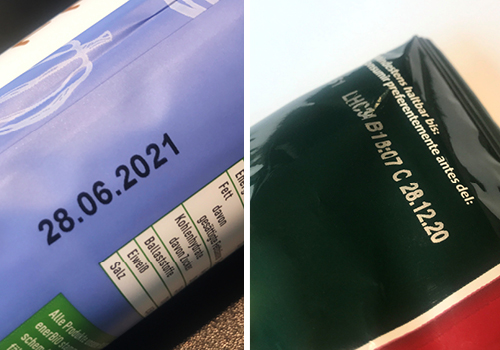

You need to print variable data in either intermittent or continuous mode in high volumes on packaging films? Thermal transfer overprinters (TTO) are predestined for flexible packaging such as tubular bags or cover films of thermoformed trays. Thanks to its compatibility and standard size the XTO fits perfectly into any existing production line.

The XTO thermal transfer overprinter is your solution:

- outstanding uptime

- highly accurate print results at high speed

- a modular concept for enhanced flexibility

- optimal ergonomics

- and the best price-performance ratio on the market

The right choice for every requirement and application - Various modules

To be prepared for any kind of direct printing our XTO Thermal Transfer Overprinter is available in various versions. With these different modules, customers are prepared for various print modes (intermittend & continious), print witdhs, print lenghts and print speeds. Please find here the overview with all available XTO versions:

XTO 2 ie/ce

The XTO is available with a 2" printhead. Depending on your requirements and application, you have to decide between the intermittent and the continuous print mode. Both the XTO 2ie and XTO 2ce are available with longer strokes. For support please contact our specialist.

XTO XL

For a larger print width, our XTO XL is exactly what you need. The XTO intermittent and continuous version is also available as XL version. "XL" indicates a deeper housing with a larger printhead up to 600mm. Match this XTO model also with a longer stroke with up to 6". Details can be found in the brochure.

XTO 22 i.nn

You need high speed and a faster process of direct printing? Then check out our latest XTO version: XTO 22 i.nn. This Thermal Transfer direct printing option includes two 2" print heads and can also be ordered with longer strokes up to a print length of 900". In case of any questions please contact our specialists.

Longer Strokes - 200, 400 OR 600 MM PRINT AREA

The XTO 2" thermal transfer overprinter in intermittent mode is also available with a stroke length of 200, 400 or 600 mm, of course with the same outstanding overprint quality.

These XTO 2" intermittent longer stroke printers are used ...

- ... to print large print areas (200/400/600 mm),

e.g. on pharmaceutical packages, ingredients on food packaging

or on chemical packaging, personal care packages and many other industries. - ... to print a repeatable print (multi-track) along the width of the packaging film,

e.g. on packaging machines that pack products in multi-lines, such as tray seal – or thermoforming machines

The benefits of the Thermal Transfer Overprinter XTO

Best price performance

The XTO has by far the best price performance ratio of all TTO machines on the market

Maximum Uptime

The ergonomic and fast ribbon change function and a tool-free printhead change within seconds ensure maximum uptime

Increased sustainability

The ribbon save function ensures that only the ribbon needed for the print is used. The result is less waste and lower costs, as the ribbon needs to be changed less frequently

Maximum integration flexibility

Thanks to its modular concept and its compatibility the XTO can be easily integrated into existing packaging machines or production lines.

Higher energy efficiency, lower costs

No compressed air is needed since a motor drives the print head. That means lower costs, easier maintenance and improved performance and uptime.

The User in focus

The XTO Thermal Transfer Overprinter has been developed on the basis of many customer interviews as well as extensive market research and with a very strong operator-centric approach. The entire machine is designed with the user in mind to make operation as easy and pleasant as possible. Therefore, the XTO is as user-friendly as it can possibly be.

The perfect fit

With its integration flexibility, productivity and extraordinary print results the XTO thermal transfer overprinter is the perfect fit for the food and pharma industry. It’s the ideal solution for coding fresh or frozen products, bakery or snack products, confectionary products or all sorts of pharmaceutical products including blister packs, wound care products or medical devices.

XTO 2IE - brochure and specifications

XTO + XLS: Print & Apply Solution with Thermal Transfer Overprint

The smart way for printing small content on labels!

The combination of the XTO intermittend Thermal Transfer Overprinter and the XLS 204 Labeler from NOVEXX Solutions provides a perfect compact Print & Apply Solution when it comes to fast printing of small content on labels.