Whether for warehouse identification or for shipping within the supply chain: pallets must be labeled clearly and professionally. On the one hand, to ensure smooth delivery and, on the other hand, to be quickly located and traceable.

The marking is done with pallet labels which are applied to the pallets manually or automatically. Linear applicators, in which the labels are applied by an applicator arm, are the most commonly used and have proven themselves many times over. If a high degree of flexibility is required, industrial robots are also used. Which application method is the right one depends mainly on business requirements. However, other dependencies such as structural conditions or special environmental influences also play a role.

Our pallet labeling solutions are all supplied with Easyplug, ZPL, and Windows driver support to ensure a high level of compatibility.

With PID 3SIXTY, our own software solution for process and data management, it is easy to map additional requirements with the special capabilities of our software.

Here you can find the different solutions:

Solutions for Pallet Labeling

STAND ALONE

FULLY AUTOMATIC

COMPLETE SOLUTION

XPU

FULLY AUTOMATIC

COMPLETE SOLUTION

XPU

- Stand-alone solution with protective housing

- Up to 200 pallets/hour

at 2 labels/pallet - Pallet is stationary during application

INTEGRATED

FULLY AUTOMATIC

PRINT & APPLY SYSTEM

XPA

FULLY AUTOMATIC

PRINT & APPLY SYSTEM

XPA

- Print & apply solution with applicator

- Easy integration into any pallet line

- Up to 200 pallets/hour (depending on the speed of pallet transportation)

- Pallet is stationary during application

MANUALLY

LABEL

PRINTER

XLP

LABEL

PRINTER

XLP

- For printing and manual application of pallet labels

- Use as a backup

ROBOT

AUTOMATIC &

FLEXIBLE:

ROBOT

AUTOMATIC &

FLEXIBLE:

ROBOT

- Robot-printer combination

- For high flexibility & accuracy

- "Future-oriented": Fast adaptation to changing requirements

- Individually programmable

Relevant for decision

Good to know: General information on pallet labeling

Good to know: General information on pallet labeling

DATA: The heart of the automatic pallet labeling

The required print data can be sent fully automatically to the pallet labeler via the PID 3SIXTY. The Data Management Software connects, manages and controls all labeling tasks in the production process in one central location - for high transparency and accuracy in the various process steps.

Using a PLC or scanner, PID 3SIXTY knows when the pallet arrives, what is on the pallet, what needs to be printed, and when the labeling process is finished.

When a pallet is finished being packed and labeled, an information is sent to the software. The pallet is released and goes to the warehouse or to shipping. The system regulates and stores the exact path of the pallet.

THE PALLET LABEL

THE PALLET LABEL

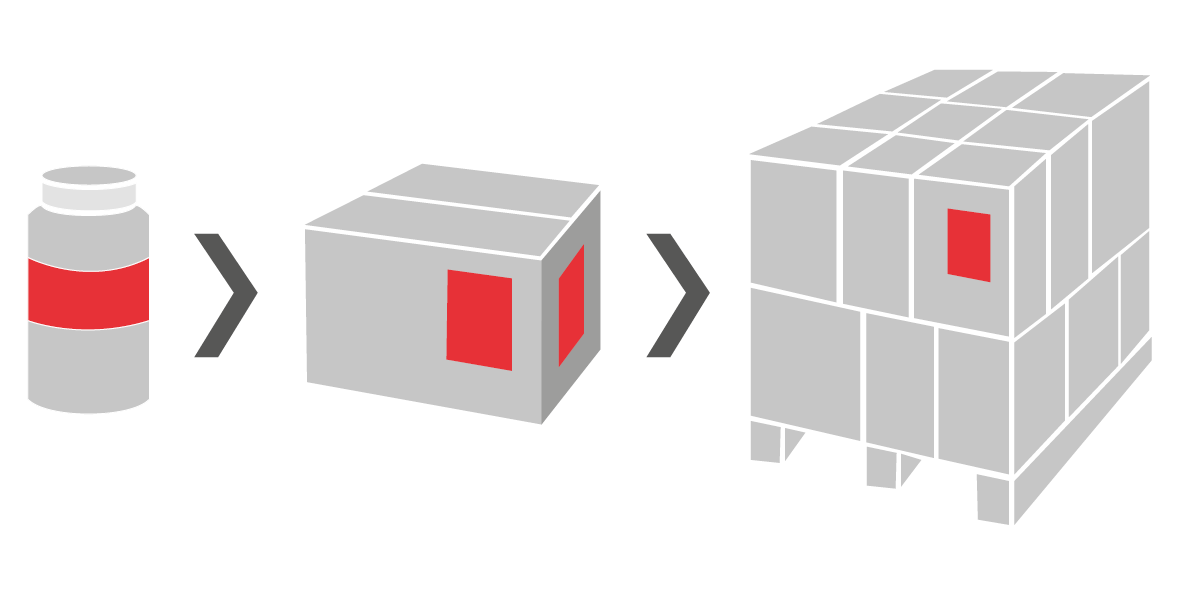

- Pallet labels carry information such as batch number, part number, product name, production time and more

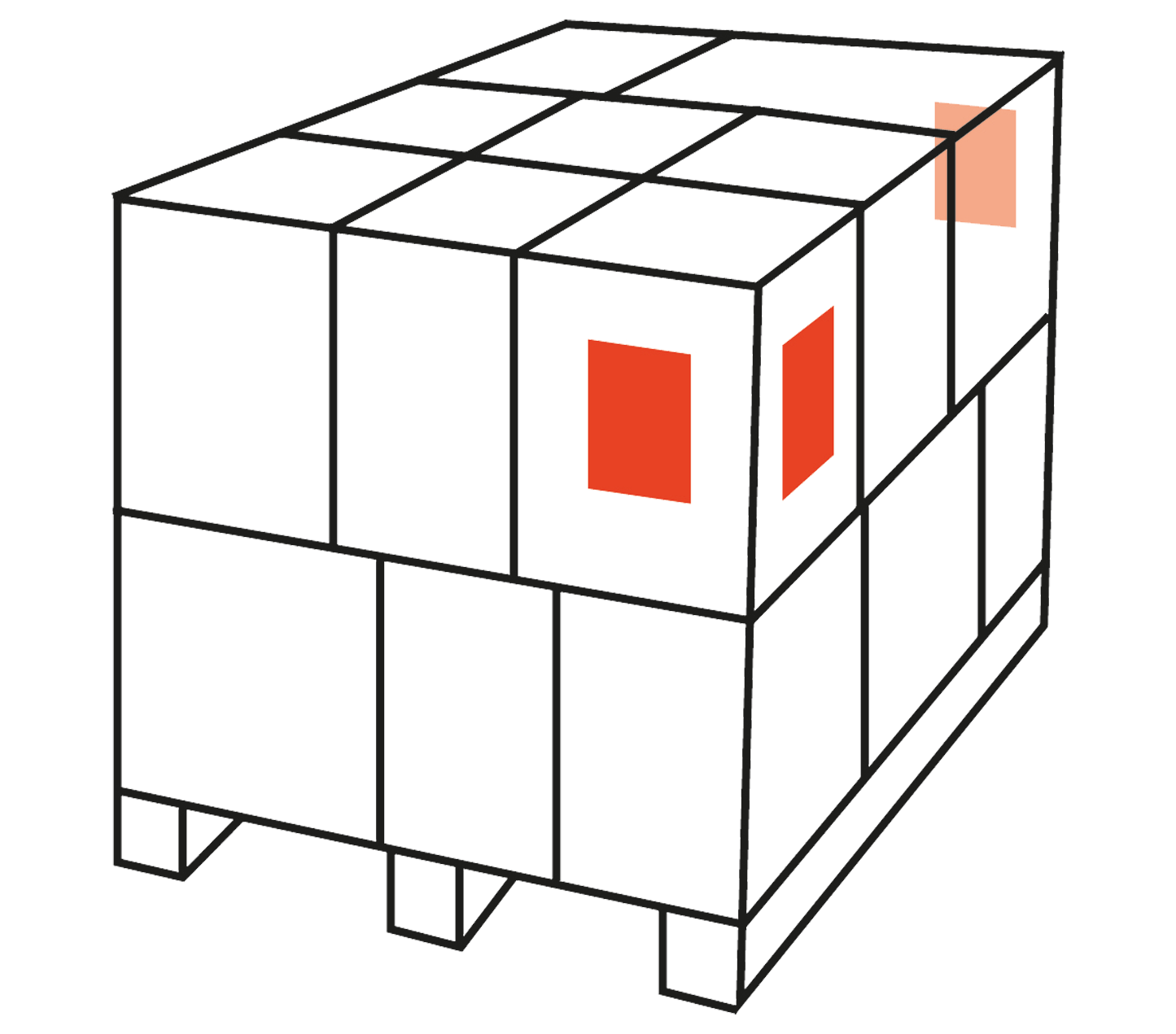

- When applying the labels, the GS1 standard specifies exact positioning

- Why? To ensure traceability, transparency and efficiency at all times in the warehouse, logistics center or at various stages of the supply chain

- A non-scannable pallet " jams" the process. This leads to wasted time and money

- The applied labels must therefore contain clearly readable and scannable information - and therefore be printed in excellent quality (usually thermal transfer printing in combination with the right label material and the matching thermal transfer ribbon)

How is the structure of a GS1 pallet label?

Segment 1 (header segment): Contains freely editable information, e.g. specification of the sender as well as the recipient.

Segment 2 (middle segment): Plain text indication of the information encoded in the barcode. The data content should be printed with a font height of at least 7 mm.

Segment 3 (foot segment): The data is encoded in the GS1-128 barcode. The SSCC is the only mandatory information on the pallet label.

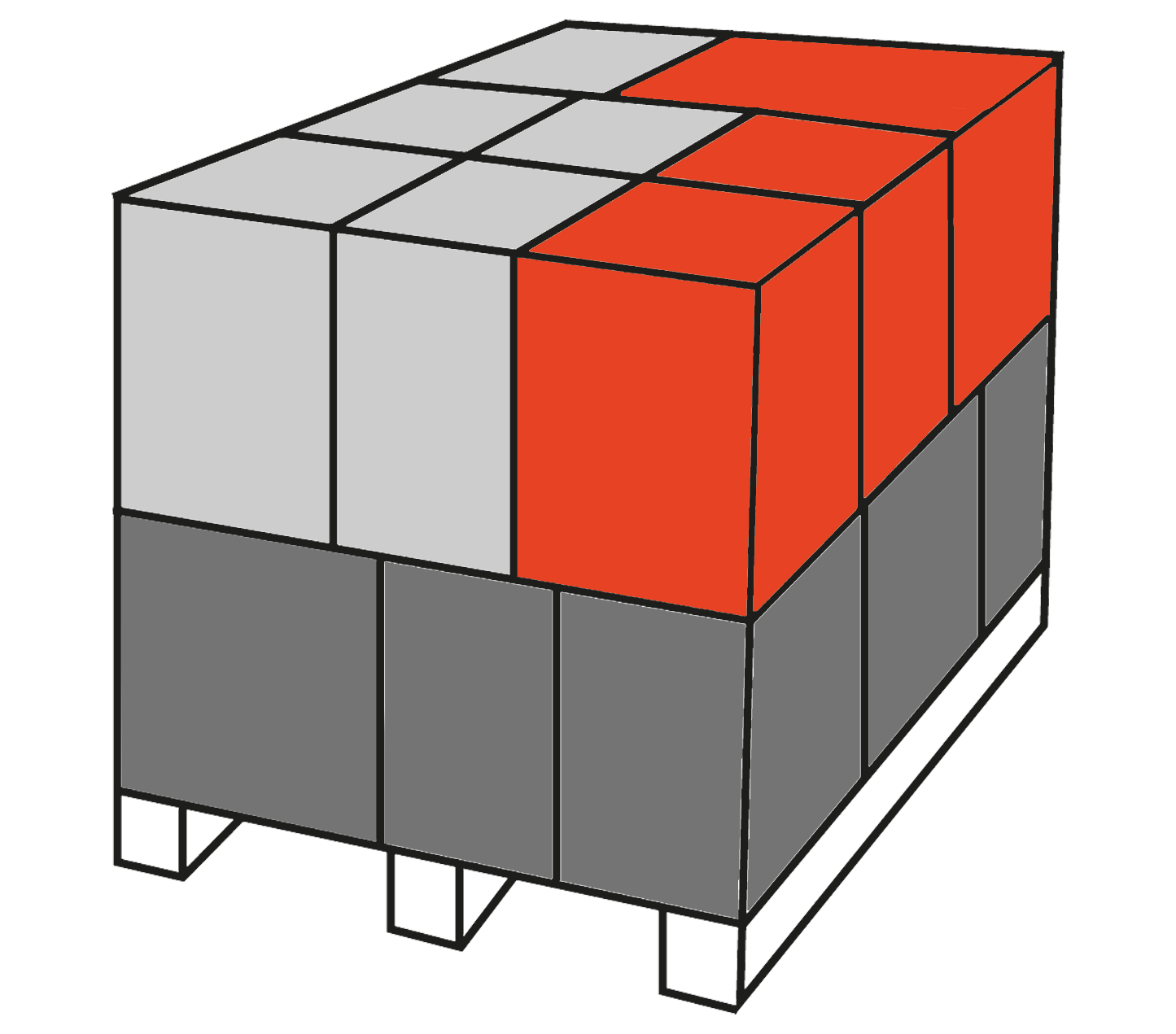

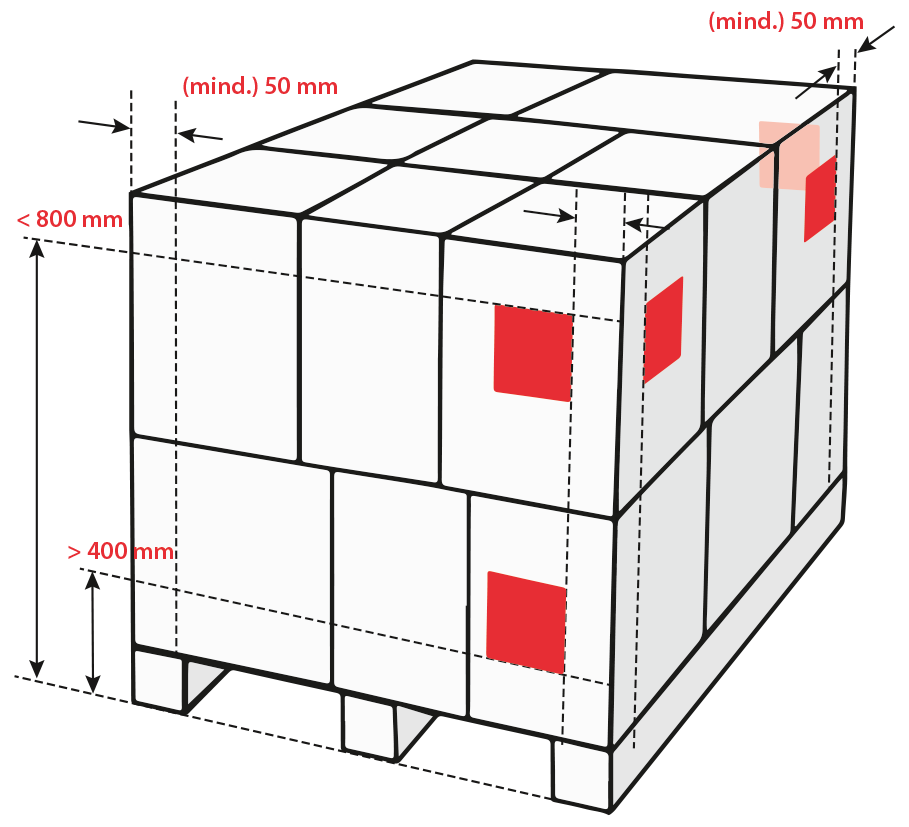

The correct positioning of a pallet label

- The barcodes on pallets should be placed between 400 mm (bottom edge of the bottom barcode) and 800 mm (top edge of the top barcode) above the standing surface

- The label should be applied with a minimum distance of 50 mm from all vertical edges to avoid damage

Identification conform to GS1

- The core element and mandatory component of the GS1 transport label is the SSCC (Serial Shipping Container Code), which enables perfect traceability of the pallet throughout the entire supply chain

- Additional information such as GLN (global location number) of the delivery address, batch number or weight information is also encoded in the GS1-128 symbology

- The fields, field lengths and codes are standardized to ensure that all goods can be identified with a barcode scanner

- All barcodes must be error-free and 100% readable

- Format of the pallet label is DIN A5 vertically

- For pallets, two labels are normally applied to two neighbouring sides

MORE INFORMATION

Do you want more information about pallet labeling and the right system for your needs? We'll gladly get in touch with you personally:

- contact us via email solutions@novexx.com or

- use our contact form >>