NOVEXX solutions success stories/Case Studies

With NOVEXX Solutions it works!

Convince yourself of our capabilities and varied range of solutions for individual requirements.

The following case studies will give you good insight!

Labeling system for maximum precision

When it comes to applying labels, maximum accuracy is required. This was also the case for a new component from a manufacturer of sanitary technology products. Therefore the company MiniTec worked togehter with NOVEXX Solutions to implement a semi-automated labeling solution that ensures this.

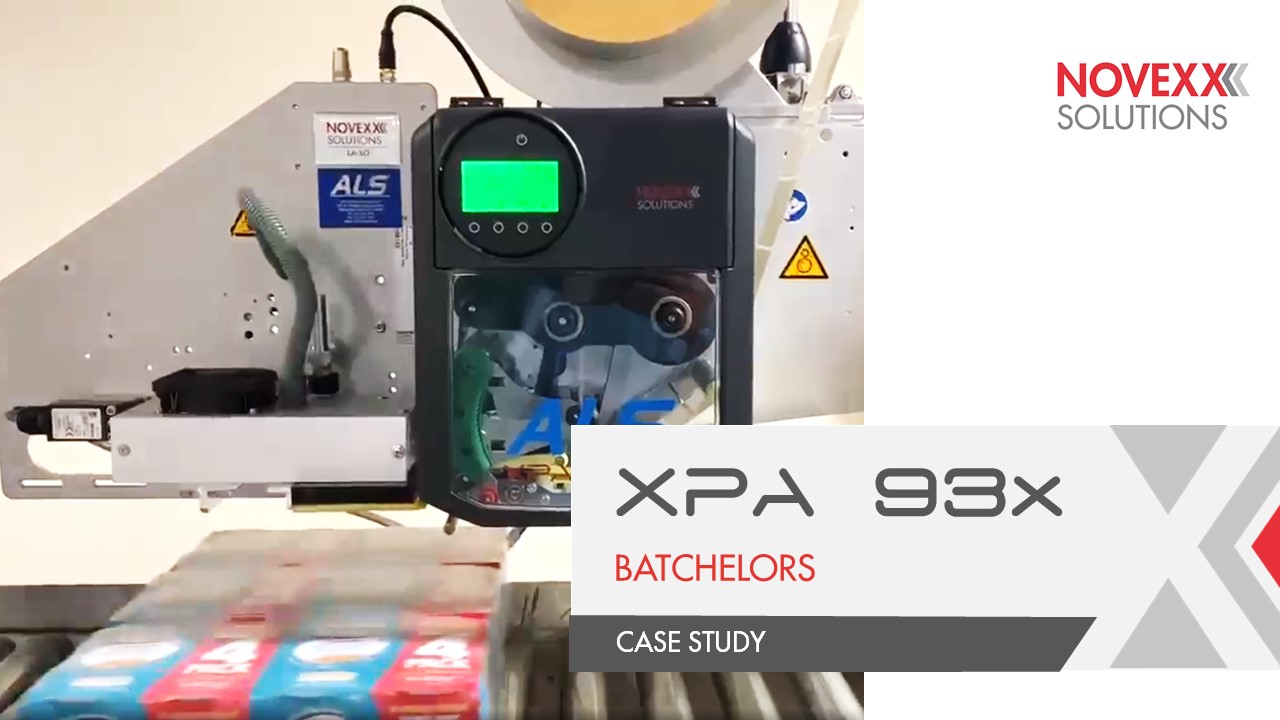

Accurate application and maximum functionality

For this project, NOVEXX Solutions manufactured a custom "salon" applicator to allow for the custom application of a label. The requirements for the label's function and placement made this project very special. The custom applicator paired with our XPA 93x were able to meet this challenge perfectly.

Compact solutions for

customized identification systems

For the development and production of compact customized identification systems, ADR uses reliable, powerful, and easy-to-install printing and labeling systems from NOVEXX Solutions. The systems are able to meet a wide range of customer requirements with maximum precision.

TAMPER-EVIDENT LABELING MACHINES FROM NOVEXX SOLUTIONS

For their identification process, the pharmaceutical company Arkopharma uses labeling systems from NOVEXX Solutions. By using NOVEXX Solutions hardware, products get labeled easily and quickly. In this special case, all products get labeled via the tamper-evident process.

Recycling Carrier paper for more sustainability

Lactalis, with its famous cheese brand PRÉSIDENT, produces 100 tons of cheese per day. The plant in Marcillat-Corcieux has 11 packaging lines, each equipped with a NOVEXX Solutions high-speed labeler. Together with Raflatac, a recycling program was implemented for the label-backing paper.

TOP & BOTTOM IDENTIFICATION OF VARIABLE-SIZED AND SHAPED MEAT PACKS

» Download

Reynolds Group Ltd is New Zealand‘s leading supplier of complete end-of-line solutions for manufacturing. They developed a incredibly flexible solution with integrtated XPA Print & Apply Systems and XLS Labeling Systems. The solution applies labels to meat packs on both the top and bottom of the variable sized and shaped products and prints real time information on each pack.

RESIDUE-FREE LABELING OF ROLLER CONTAINERS

With a highly efficient solution for the identification of roller containers, NOVEXX Solutions is accelerating goods logistics in the distribution centers of a Dutch supermarket chain.

To date, four of the largest retailers in the Netherlands have adopted this solution.

BEIERSDORF STANDARDIZES PRODUCTION WITH HELP OF TRACE-IT® SOFTWARE SOLUTION.

The NOVEXX Solutions Trace-it® Software ensures visibility across Beiersdorf’s global manufacturing chain.

VARTA MICROBATTERY GMBH: INDIVIDUAL REQUIREMENTS. CUSTOMIZED SOLUTIONS.

VARTA Microbattery GmbH uses the Print & Apply range of NOVEXX Solutions to increase productivity and reduce costs.