INTEGRATED Pallet Labeling: XPA 936 with ROTOR-Long APPLIcATOR

- Precise application of up to 2 GS1-compliant DIN A5 labels according to GS1 standard on the stopped pallet

- Cost-efficient, fully automated solution

- Perfect 300 dpi print quality even in harsh logistics environments

- Uncomplicated integration: directly into the production line, quickly ready for use

- Installation: to the left or right of the conveyor belt, no protective housing required

- Intelligent: remote operability thanks to web interface for remote access via any PC, mobile device or industrial panel PC, many flexibly adaptable interfaces

- Maximum user-friendliness: fast material change, freely rotatable display,

- 100% tool-free maintenance

- Sustainable: less waste and lower costs thanks to film saving function

Download brochure

Are you looking for a special solution for pallet labeling?

The right print and apply system for every challenge:

STAND ALONE: FULLY AUTOMATIC COMPLETE SOLUTION XPU

- Stand-alone solution with protective enclosure for harsh environments (humidity, dirt...)

- Pallet stands still while applying GS1 compliant DIN A5 labels

- Labeling of 2 sides with only one pallet stop, 3-sided labeling possible

- Up to 200 pallets/hour with 2 labels/pallet

- Housing with integrated XPA 936 and 2-side applicator

- Fully automatic, PLC controlled, masters 24/7 applications

- Can be installed on the left or right side of the conveyor

- Scanner for barcode validation

Manual: LABEL PRINTER XLP

- Perfect printing & manual application of pallet labels

- Cost-effective entry into pallet labeling when small quantities of pallets need to be labeled

- Maximum ease of use for simplest operation

- Intelligent printing for all digital challenges

- 1:1 back-up system for XPU and XPA/ALX

automated & FLEXIBLe: ROBOT

- Robot-printer combination for high flexibility & accuracy

- Labels hard-to-reach positions on the pallet that cannot be reached with an XPU or XPA

- Applies multiple labels to different locations on a pallet

- Consists of e.g. an NXX printing (& labeling) system and a robotic arm

- The hardware can be complemented by PID 3SIXTY >> software, which provides an MES and a PLC interface

- "Future-oriented": Fast adaptation, flexible programming

THE RIGHT SOLUTION FOR ANY REQUIREMENT

THE RIGHT SOLUTION FOR ANY REQUIREMENT

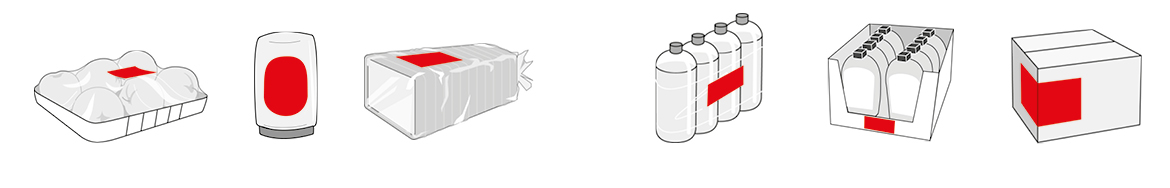

The NOVEXX Solutions standard applicators allow various application possibilities for products, cartons or pallets.