High-resolution and flexible

Thermal Transfer Overprinting

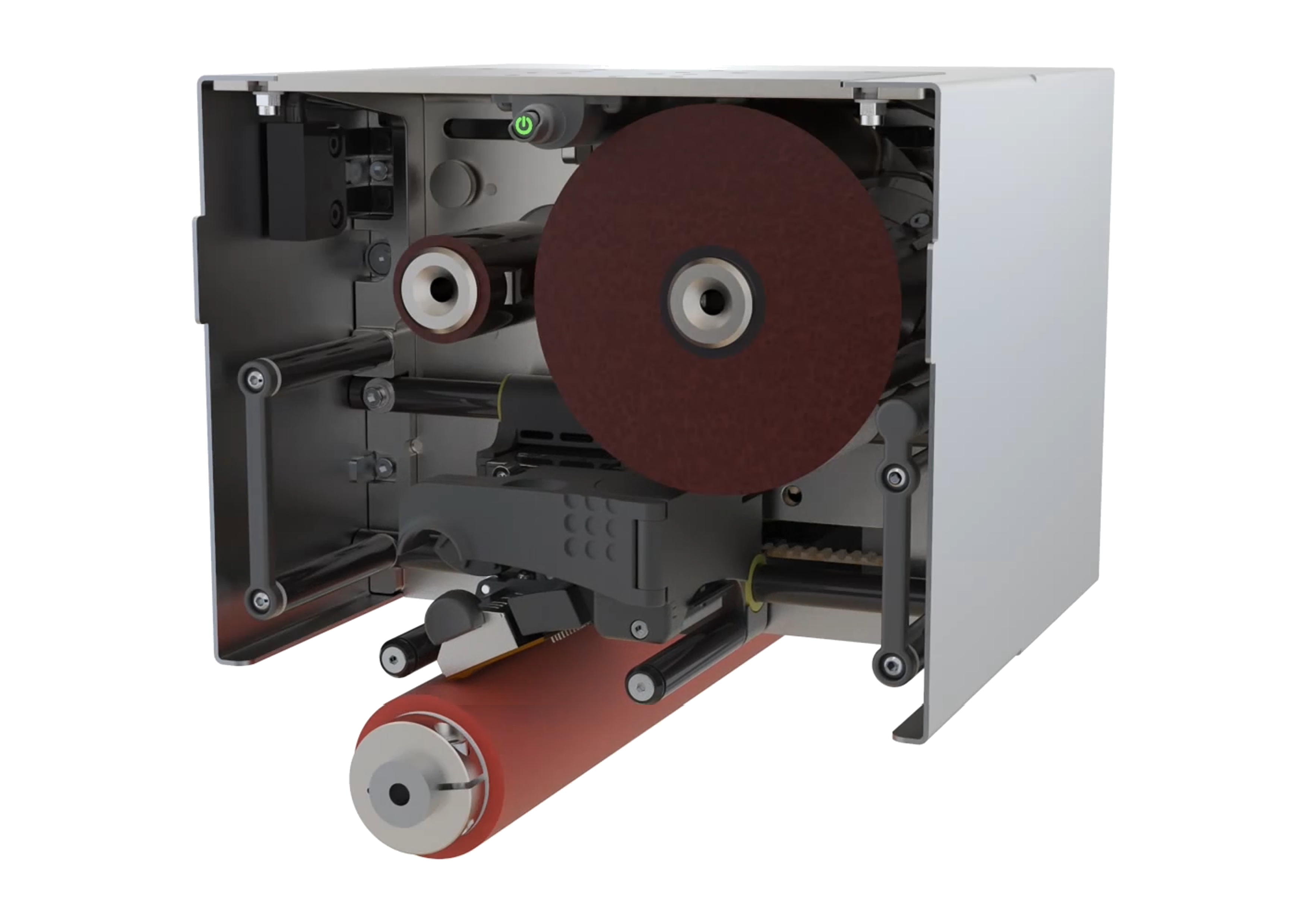

Thermal transfer overprinting (TTO) is the ideal solution for transferring variable data with very high resolution onto flexible packaging material such as films (polypropylene, polyethylene etc.), flexible aluminium, labels, papers, tyvek (medical industry) and gloss cards. Unlike other inkjet technologies, TT overprinters are in direct contact with the substrate, allowing better quality text, graphics and barcodes. This very clean printing process also ensures that the appearance/design of the packaging to be printed remains unchanged. Direct thermal transfer printing can be used to print simple date codes and batch codes, logos, product descriptions, ingredients lists, nutritional panels and fully compliant barcodes in superior quality.

Good to know – key facts about TTO technology

TTO printers need to be integrated into a host machine, which is usually an FFS (form, fill and seal) packaging machine

The two types of TTO machines are either continuous (printhead is static) or intermittent (printhead moves) printing depending on which host machine is used

TTO can be also used in combination with labelers, where small, variable text is printed on the label before the label is attached to the product

The printing resolution is 300 dpi using corner-edge print technology, allowing very good quality print of variable data

TTO is used to print dates, times, traceability info, barcodes, logos, ingredient statements, food critical information (allergies, calories ...), how-to-use information as well as promotional messaging

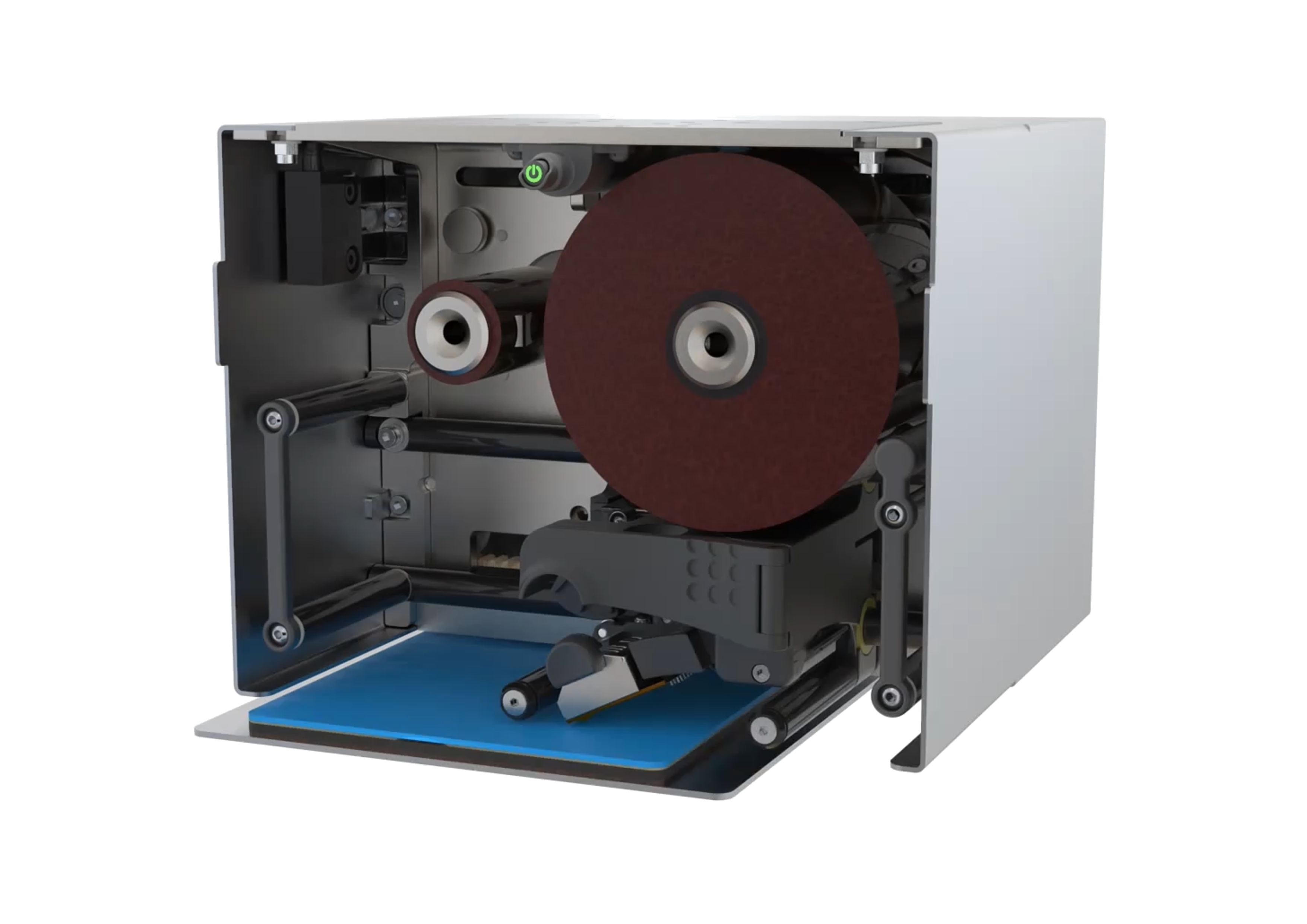

How TTO works

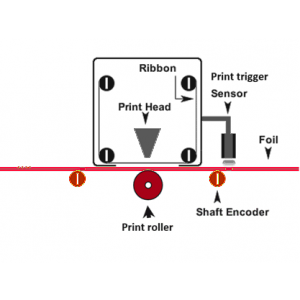

Intermittent versus continuous printing

Continuous printing

The packaging film is moving while printing.

The printhead is static, printing on a rubber print roller.

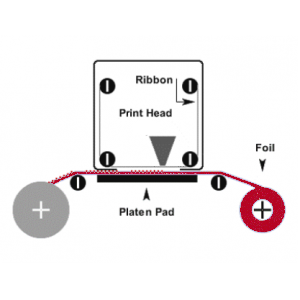

Intermittent printing

The packaging film is standing still while printing.

Only the printhead carriage moves, printing on a rubber print plate.

Advantages of the TTO technology

HIGH PRODUCTIVITY

Variable data can be changed in real time for each print job without interrupting the production chain.

FIRST CLASS QUALITY AND DURABILITY

The thermal transfer printing process delivers high-resolution, sharp and clean print results that are resistant to damage from scratching or rubbing, frequent washing, and external elements such as oil, petrol and alcohol.

FLEXIBILITY

Products can be printed in all situations, either stationary or moving. The surfaces are modified in real time in order to align them to the printer.

ECO COMPATIBILITY

Thermal transfer overprinting technology avoids the use of liquid ink that have a high environment impact and the need for drying and minimizes the space needed for stocks in the warehouse.